The Ultimate Guide to Custom Plush Toys Manufacturing

I hope you enjoy reading this blog post. If you are looking for custom plush toys, click here.

If you’ve ever wondered how your favorite plush toys are made or how to bring your own designs to life, this guide is for you.

Table of Contents

Last Updated on February 26, 2025 by PlushLab Team

Custom plush toys are not just for children anymore—they’ve become an essential promotional tool, collectible item, and even a unique expression of creativity for brands and individuals alike. Whether you’re a designer, a business owner, or just someone with a great idea, knowing how custom plush toys are made can help you turn your vision into a tangible product that stands out. In this guide, we’ll walk you through the process of custom plush toy manufacturing, the factors that affect pricing, and tips on selecting the right manufacturer for your project.

What Are Custom Plush Toys?

Custom plush toys are soft, stuffed toys made to a specific design or specification. They can represent a character, mascot or a unique idea and can range from simple stuffed animals to intricate plush figures that require specialized designs. Custom plush toys are beautiful, fully customized plush toys developed for customers to meet their needs whether for promotional giveaways, mascots or limited-edition merchandise.

Why Choose Custom Plush Toys?

There are many reasons why custom plush toys are a great choice for businesses and individuals alike:

- Brand Promotion: Custom plush toys are highly effective at increasing brand visibility. By creating a plush version of your brand’s mascot or logo, you can give your audience a fun and memorable product that keeps your brand top of mind.

Collectible Appeal: Plush toys are timeless. They appeal to all ages and make fantastic collector’s items. Whether for an event, holiday promotion, or limited edition release, a well-designed plush toy can attract attention and build excitement.

Perfect for Gifting: Whether for corporate gifts, charity events, or personal milestones, custom plush toys are always a hit. Their versatility makes them suitable for a wide range of occasions.

The Custom Plush Toy Manufacturing Process

Understanding how custom plush toys are manufactured can help you ensure you get the best quality product. Here’s a breakdown of the process:

1. Design & Concept

It all starts with an idea. Once you know what you want your plush toy to look like, the first step is to work with a manufacturer to take your idea and turn it into a design. You’ll need to choose your materials, determine the size, colors, and aesthetics of your plush toy.

You can supply sketches, photos, or 3D models, and they’ll help you finalize the design for you and make it ready for mass production. This is also when you finalize any special requirements such as embroidery.

2. Material Selection

The materials used for custom plush toys are crucial for both safety and comfort. Common materials include:

- Fabrics: Soft fabrics like polyester and cotton are used for the outer shell.

- Filling: The stuffing material is typically polyester fiberfill, known for being lightweight and safe.

- Safety Standards: Make sure that all materials comply with safety standards, especially if the plush toy is intended for children.

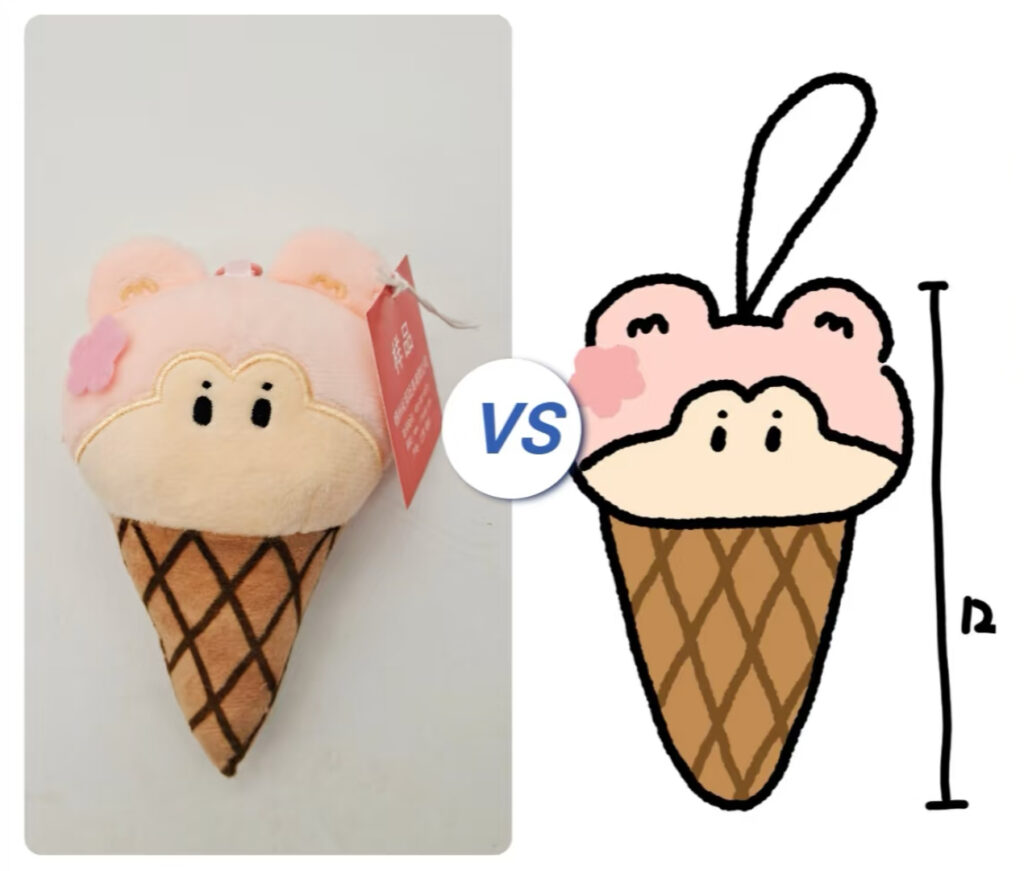

3. Prototype & Sampling

Before full production begins, a prototype or sample is created based on your design. This gives you a chance to evaluate the quality of materials, the accuracy of the design, and any adjustments that may be needed. You’ll be able to assess the color, stitching, and overall feel of the toy, ensuring that it meets your expectations.

4. Production

Once the sample is approved, the manufacturing process begins. This includes cutting, sewing, stuffing, and assembling all the pieces. Depending on the complexity of the design, this process can take anywhere from a few days to several weeks.

5. Quality Control

Quality control is a critical step in ensuring that each plush toy meets safety and quality standards. Manufacturers conduct various checks throughout the production process to confirm that the toys are free of defects, have secure stitching, and are made from safe materials. Certifications such as EN71 (Europe) or ASTM F963 (USA) are often required for safety compliance.

6. Packaging & Shipping

After production, the plush toys are packaged carefully to prevent damage during shipping. Packaging options vary, depending on the type of product and your requirements. Your manufacturer will ensure that your toys are properly packed and ready to be shipped to their final destination.

Factors Affecting the Cost of Custom Plush Toys

Several factors influence the price of custom plush toys, so it’s important to understand them before getting a quote:

- Quantity: The more units you order, the lower the price per piece. Bulk orders help to reduce production costs significantly.

- Complexity of Design: Intricate designs with multiple features, such as embroidery, accessories, or specific color patterns, may raise the price.

- Materials: Higher-quality fabrics or specialty materials may increase the cost, but they also ensure better durability and safety.

- Size: Larger plush toys generally cost more due to the increased amount of material and labor required.

- Safety Standards: Compliance with safety regulations and certifications often adds to the overall cost but is crucial, especially for toys aimed at children.

How to Choose the Right Custom Plush Toy Manufacturer

Choosing the right manufacturer can make or break your custom plush toy project. Here are some tips to help you select the best supplier:

- Experience: Look for a manufacturer with experience in custom plush toy production, especially one that has worked on similar projects.

- Quality Control: Ensure that the manufacturer follows strict quality control measures and can provide certifications for safety standards.

- Customization Capabilities: Check that the manufacturer can meet your customization needs, from design to materials to features.

- Communication: Effective communication is key. A good manufacturer should be responsive and able to guide you through the entire process.

Conclusion

Custom plush toys are a fun and versatile way to express creativity, promote your brand, or create memorable gifts. By understanding the manufacturing process and selecting the right manufacturer, you can ensure that your custom plush toy project is a success.

If you’re ready to start designing your own custom plush toys, contact us today for a free consultation. We’re here to help you bring your ideas to life!

Discover the Custom Plush Toys for Your Brand with Us

At PlushLab, we specialize in creating high-quality custom plush toys that perfectly reflect your brand, character, or idea. Whether you’re looking for a fun promotional item, a unique gift, or a standout collectible, we offer a range of customization options to bring your concept to life. From design consultation to production and shipping, we’re with you every step of the way.

Explore the endless possibilities of custom plush toys with us. Our team is ready to help you create something special that will resonate with your audience and leave a lasting impression.

Request Free Quote Now!

Hey there, I’m Anna!

Hi, I'm the author of this post, and I have been in this field for more than 5 years. If you want to custom plush toy, feel free to ask me any questions.